It is well established that the performance of Japanese aircraft engines in WWII was limited by the suboptimal fuels available at the time, among other factors. As a result, in order to achieve boost pressures in the ballpark of high-power Allied engines, it was necessary to rely on water injection even at nominal operation.

Nonetheless, aviation enthusiasts often speculate on the performance of Japanese aircraft if they were supplied with high-octane fuels and up-rated appropriately. This is partially due to the fact that there are widespread myths of superior performance numbers being achieved with Japanese aircraft using American high-octane fuel, when in reality, in most if not all cases these numbers are wartime calculations using inadequate data.

Nonetheless, it is an interesting question. In a past article on the Ki-84, I wrote that “it’s unknown how much additional pressure a Japanese mass-produced Ha-45 could even handle.” Thanks to an article I recently read in the book「日本航空学術史 1910-1945」(Aeronatical Researches in Japan 1910-1945), there is a satisfactory answer to this.

Single-Cylinder Test Units

From April 1939 to March 1944, the Engine Department of the Navy Aviation Technical Arsenal (Kūgishō) manufactured single cylinder testers and conducted tests on the power enhancement of aircraft engines using these machines.

In the past, these experiments relied on foreign imported single-cylinder testers manufactured by the American SPE Company (Self-Priming Pump and Engineering Company) and the German DVL (Deutsche Versuchsanstalt für Luftfahrtforschung). However, this posed a problem when experiments resulted in a broken part of the test units, as they were not domestically produced.

To solve this problem, it was decided to manufacture a domestic single-cylinder tester that could use Japanese mass-produced engine components. The single-cylinder tester was to have easily changed experimental parameters and be able to withstand harsh operation.

For changing the engine compression ratio, the DVL method was adopted in which the engine cylinder mounting base could be vertically adjusted with a handle. An SPE type balancing rod was used to manage the balancing of dynamic forces at high operating RPM. The valvetrain was designed so that it could be adjusted with a dolly lever so the angle of the valves and pushrods would not have to be changed according to whichever cylinder of an actual engine was installed, and the cams and dolly levers could be made to match each engine. Crankshafts were made in several different strokes with a shared diameter. The auxiliary shaft had a large amount of attachment points so that many engine accessories could be installed.

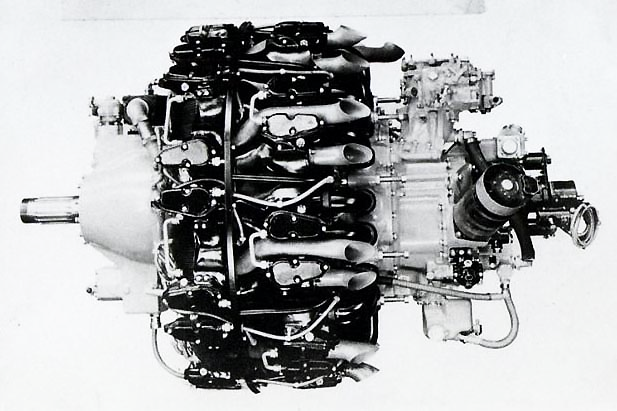

About 20 units were manufactured in total, with examples made for the Homare, Kinsei, Amakaze, and Kamikaze engines. These single-cylinder testers were distributed to fuel depots and the Central Aviation Research Institute. Later models were being developed for water-cooled engines and prototype engines, but were not completed due to the deteriorating war situation.

Power Enhancement Tests

For tests on enhancing the power of engines, the Kinsei and Homare units were chiefly employed. Various factors would be adjusted individually to increase power output such as the compression ratio, RPM, boost pressure, air/fuel mixture, ignition timing, and type of fuel. The results of testing were plotted on a graph with power as the horizontal axis and cylinder temperature as the vertical axis. The objective was to increase power with as little rise in cylinder temperature as possible, so a shallow curve was desired. Generally speaking, the most promising results were achieved by increasing the RPM or boost pressure.

With the Homare test unit, a two-stage roots supercharger with a supercharging capacity of up to +1500 mmHg boost (2.974 atm, 88.98 inHg) was attached, and tests were conducted using highly detonation-resistant fuel consisting of iso-octane mixed with 0.15% tetraethyl lead, benzol, toluol, and other aromatics, in conjunction with water-methanol injection. It was confirmed that the Homare could withstand being supercharged up to about +800 mmHg (2.053 atm, 61.42 inHg). This is the mechanical limitation of the engine.

As designed, the nominal operating boost pressure of the Homare Model 21 / Ha-45 engine was +350 mmHg (1.461 atm, 43.70 inHg), or +500 mmHg (1.658 atm, 49.61 inHg) at takeoff/emergency operation.

Source

- 日本航空学術史 1910-1945. (2021). 三樹書房.