Author: qaz

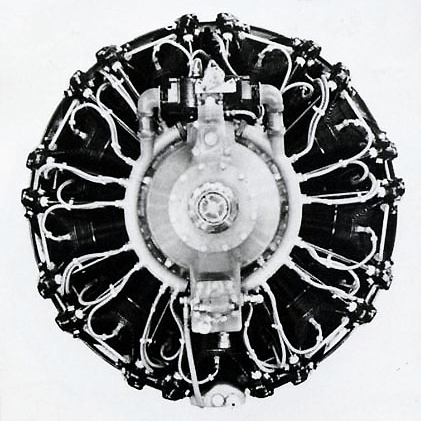

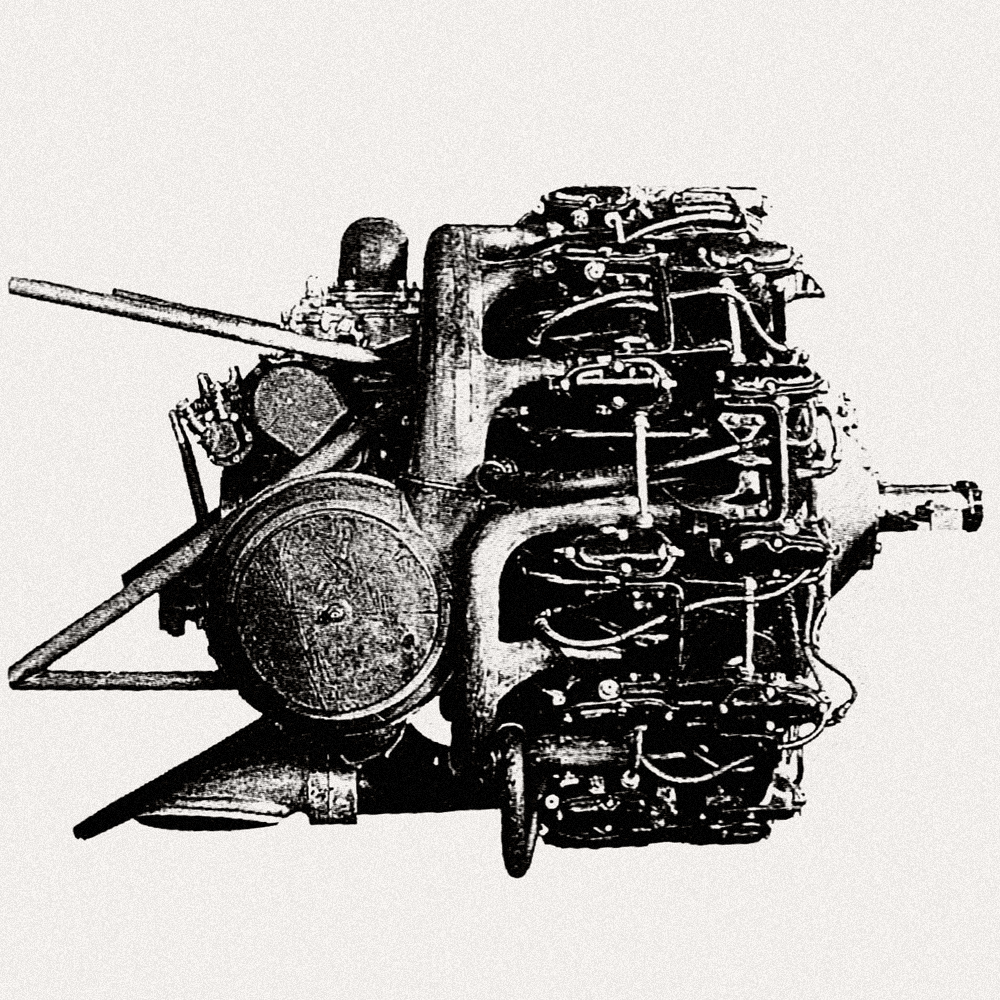

The Uprating Capacity of the Ha-45 / Homare Engine

It is well established that the performance of Japanese aircraft engines in WWII was limited by the suboptimal fuels available at the time, among other factors. As a result, in order to achieve boost pressures in the ballpark of high-power Allied engines, it was necessary to rely on water injection even at nominal operation. Nonetheless,…

About the Performance of Type 4 Fighter (Ki-84) ー Pt.2

This is an update to the previous article about the performance of the Type 4 Fighter (Ki-84), addressing some errors and new information that I have found since writing it. It is not so much an article as a set of separate points. The original article is here: Ha-45 Special is Ha-45-11, not Ha-45-12 The…

What Was the A6M4?

The A6M4 is an “unknown” variant of the Zero Fighter that has been described as a variety of things over the years. The most common theory in English writing is that A6M4 was a designation for a type of Zero fitted with a turbocharger to its Sakae engine. Another common theory is that the number…

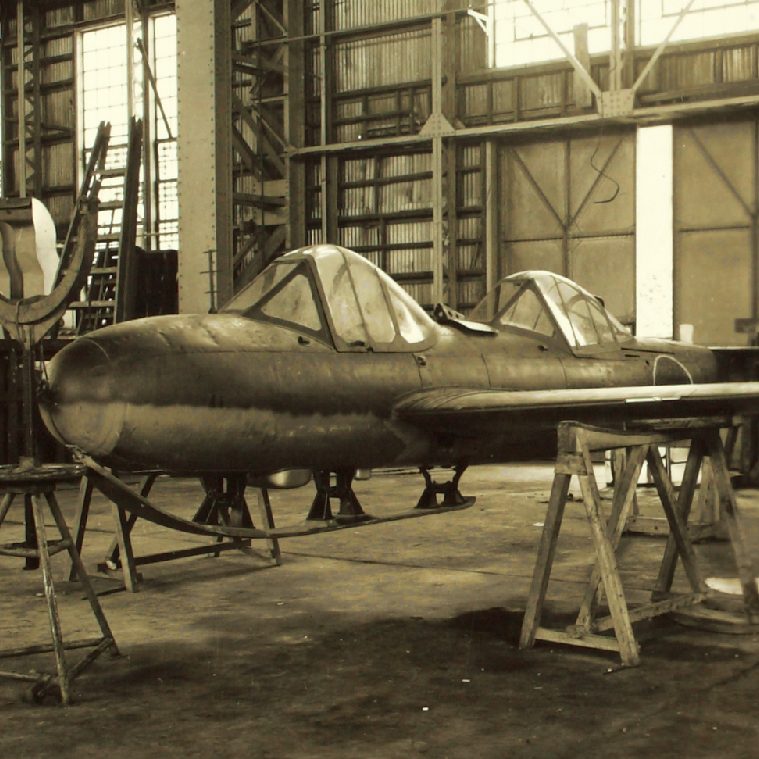

Identifying Japanese Jets Captured by the US in 1945

Following the surrender of Japan in August 1945, the American occupational authorities sought to gather whatever aircraft developments were of potential interest. Naturally, the most cutting edge planes and engines developed in Japan were high on this list. More than a few of these projects had already been destroyed by Japanese orders immediately issued to…

Ōka Trainers: MXY7-K1, MXY7-K2, & Wakazakura

This article is an attempt to clarify the details of the different training aircraft that were developed for the Japanese Navy’s late-war special attacker ‘Ōka’. The designations and purposes of the Ōka trainers are often confused, not only in English but even in Japanese publications. Using a few historical materials, we can correctly identify them…