By the 1930s, the practical speed limit of piston-engined aircraft was being approached for the first time. Before a propeller-driven airplane can approach the speed of sound, there is a period where the blade tips must reach supersonic speed, resulting in massive turbulence and loss of efficiency. This effect imposes a rough ‘limit’ on the horizontal top speed of piston-engined airplanes at around 800 kilometers per hour. Globally, the Macchi M.C.72 seaplane set an airspeed record of 709.2 km/h in 1934, followed by the 755.1 km/h record set by a Messerschmitt Me 209 in 1939, which remained the piston airspeed record for the following 3 decades, illustrating the difficulty to advance near the practical limit.

The limits of piston-engined aircraft were the main drive behind the development of the gas turbine or jet engine, discarding the propeller, which rapidly loses thrust at high speeds, for propulsion by the exhaust of a high-speed jet of heated gas. This method of propulsion would eventually enable aircraft to reach much higher speeds with greater efficiency than propeller planes.

Early developments of gas turbine propulsion began to take shape in Europe by the 1930s and culminated with the nearly simultaneous prototyping of the ‘Whittle Unit’ in Britain and the ‘HeS 1’ in Germany; the first two examples of the turbojet engine, in 1937. Further development to make such designs practical resulted in the flight of the first jet plane, Germany’s Heinkel He 178, in 1939, followed by the Britain’s Gloster E.28/39 in 1941.

As research advanced overseas, the situation within Japan, which up to this point had only recently caught up to the conventional aero-engine technology of the Western world, was isolated. While the experimentation into jet engines in Britain and Germany eventually resulted in widespread development and practical applications in these countries, globally it was largely unknown and had not made an impression. Because the jet engine was not yet attractive to the Japanese military, and companies were tied up in the development of conventional piston engines regardless, the conception of the Japanese jet engine was left to pioneers working independently on their own initiative.

Early Interest Within Japan

Interest in Japan regarding technology related to the jet engine dates back as far as the 1920s. Around this time, Navy Lieutenant Kōichi Hanashima (花島 孝一) was interested in turbines and other rotating machines from Europe. In 1920, shortly after his promotion to Lieutenant-commander, he went on a business trip to France. During this trip, Hanashima purchased 10 Rateau turbochargers for the Suiza engine and returned to Japan with these souvenirs the same year.

Hanashima, who graduated from the Navy Engineering College at the top of the class, was a well-educated man who always had a keen eye on the latest developments of aviation technology. He foresaw possibilities in the application of this technology, however, at that time he could not promote domestic interest in this field. One Rateau turbocharger ended up in the possession of the Tokyo Imperial University for study.

In December 1930, now a Navy Captain, Hanashima became the General Manager of the Yokosuka Arsenal Engine Testing Department. At that time, the group under him only consisted of Lieutenant Toshio Kondou and a few other members. In 1932, the various Navy aviation research departments such as the Engine Testing Department and Aircraft Testing Department of the Yokosuka Arsenal, and the Giken Aviation Research Department at Kakamigahara, were reorganized into the Yokosuka Air Arsenal, where Hanashima retained his position in the Engine Department. Over time the facilities of the arsenal were expanded, and by 1936 it was almost complete.

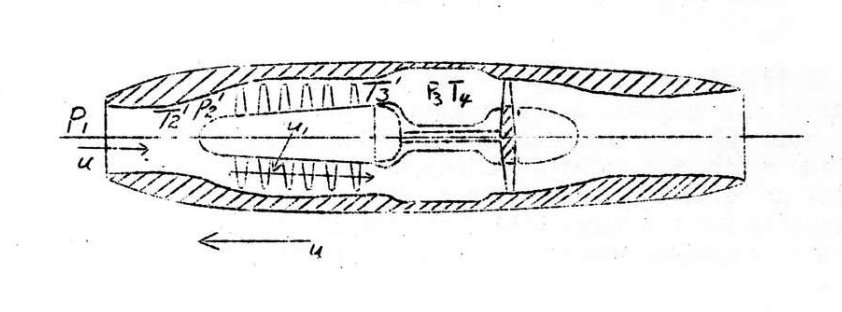

Early European jet development was now in swing, and at the time, somewhat public, due to lack of government interest. As fragments of this information began to trickle into Japan from overseas, the attention of a few researchers in Japan was caught. Rear-admiral Hanashima, who by 1936 had become aware of jet patent literature from the likes of Robert Goddard, Frank Whittle, and Secondo Campini, was highly captivated with the concept. He quickly formed a research group, and with the cooperation of Tokyo Imperial University and Mitsubishi Heavy Industries, began studies on the jet engine. While European researches at that time were largely focused on the motorjet and turbojet configurations, Hanashima was most interested in the simple ramjet format.

Tokyo Imperial University started the study of propulsive ducts in 1937. This theoretical research was mainly headed by Professor Keizo Hatta and Professor Fujio Nakanishi. Attention was focused on the ramjet, and experiments were conducted relating to airflow through various ramjet internal ducts. One of their students, Yoshitarō Hibi, was highly interested in the experiments, and after graduating from the Tokyo Imperial University joined Mitsubishi and started working with ramjets. Experiments with scale models in external airflow were conducted in 1939 and later.

The theoretical and material development that goes into the research of jet engines was not so high in Japan at that time, due to its isolated position from the rest of the technological world. Due to this, the aforementioned research works were slow, troubled, and full of unknowns.

However, the situation changed when Tokiyasu Tanegashima arrived on the scene around 1938.

Tokiyasu Tanegashima

Tokiyasu Tanegashima (種子島 時休) was born in Yokosuka City on July 20, 1902. A descendant of the Tanegashima clan, his ancestry included Tokitaka Tanegashima, who is famous for introducing the firearm to Japan in the 1540s. Due to this, he picked up the nickname ‘Teppou’ (gun) in his childhood. Mr. Tanegashima entered the Naval Engineering College in 1918, graduated in 1921, and served on the largest Japanese battleship at that time ‘Mutsu’, becoming interested in power plants while often visiting the boiler room. In 1927, he discovered the book “Steam and Gas Turbines” by Aurel Stodola, which enclosed an explanation of the gas turbine engine at that time.

Afterward, Tanegashima entered the Navy Air Service and was appointed to investigate aircraft engines. He passed the technical course of the Navy Staff College in 1929 and entered the Tokyo Imperial University Aeronautics Department the next year. Here he studied the basics of aircraft engines, including early research regarding gas turbines, which was highly rare at the time. He graduated from the Aeronautics Department in 1933 and became the head of the Hiro Navy Arsenal Engine Department Assembly Plant, meeting Osamu Nagano (永野 治), his subordinate and later an invaluable designer of jet engines. Tanegashima was ordered to travel to Paris in 1935 to survey aero engines and fighter-mounted machine guns, touring various related companies throughout Western Europe.

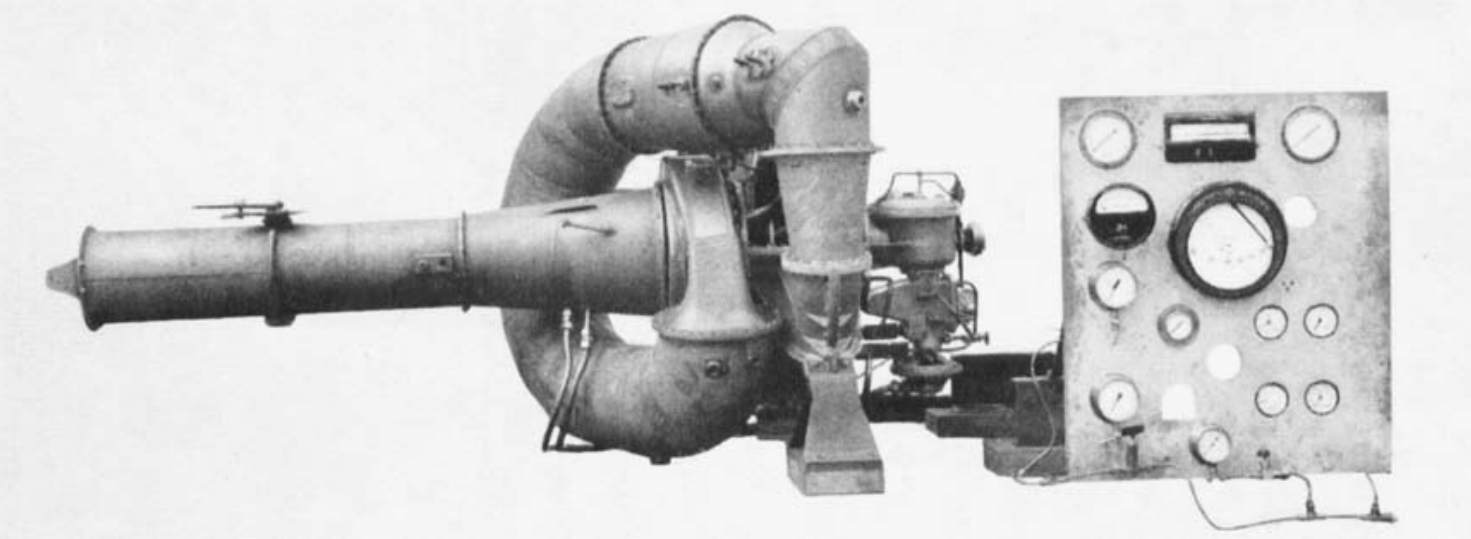

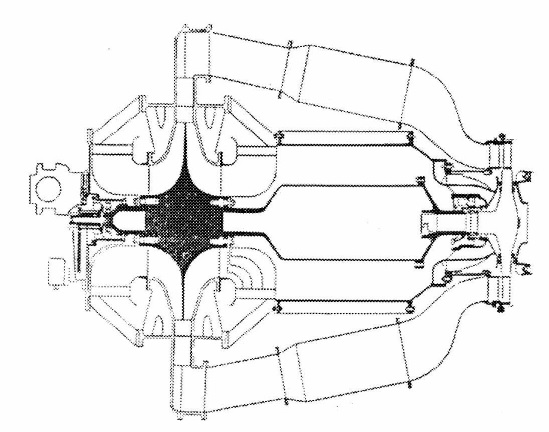

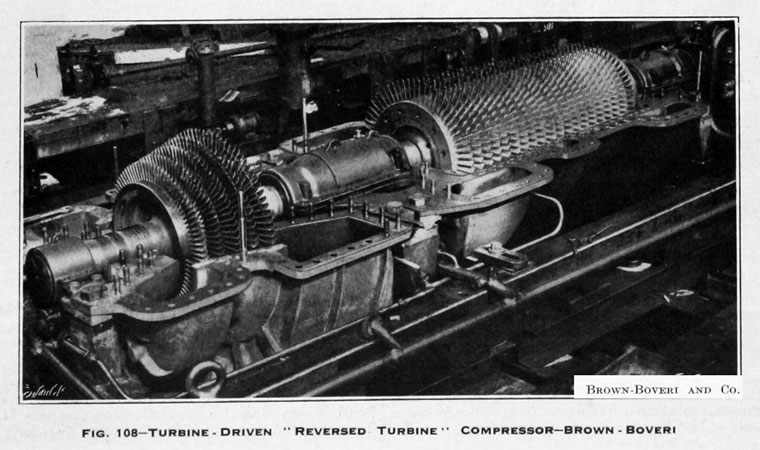

Tanegashima used this time to also investigate the situation of the gas turbine in Europe, but he was dissatisfied by the lack of information in France, Germany, Italy, and England. However, in 1936 while visiting Switzerland for the Oerlikon company, Tanegashima visited Brown-Boveri, an electrical engineering company that was involved in the manufacture of turbines for general industry. The chief engineer Mr. Klingerfuss displayed drawings of gas turbines, as well as an actual example of an exhaust gas turbine. Tanegashima ordered Brown-Boveri to manufacture two turbochargers for 1,000 hp aircraft engines at 10,000 yen each and was recalled to Japan in 1937 enthusiastic about the possibilities of gas turbines.

Upon his return, Tanegashima was immediately appointed to Yokosuka Air Arsenal (henceforth ‘Kūgishō’) as the Chief of Service Engineers for the 1st Engine Factory, chief of the factory. The main responsibilities of the Chief of Service Engineers were to examine and test prototype engines, improve existing engines, perform failure tests to apply countermeasures, maintain engines for flight testing planes, and support experiment planning. So the 1st Engine Factory was constantly tied up with work applying countermeasures for various engine malfunctions, which were very serious and labor-intensive due to the pilots trusting their lives in the reliability of those machines.

However, around the time of 1940, complaints about aircraft engines disappeared due to war enthusiasm, and Tanegashima used this newfound free time to study the gas turbine concept closely in his lab. The second volume of the English translation of “Steam and Gas Turbines”, which could be considered Tanegashima’s bible, was always on his desk. During the early period, working only with his assistant engineer Watanabe Sadaki, he created two crude apparatus for confirming the theoretics of jet ducts and combustion chambers. The results were satisfactory, which reinforced the feeling that it was possible to manufacture a jet engine. Gradually he took in more engineers that gathered around in interest, such as Osamu Nagano, who was assigned to the same department.

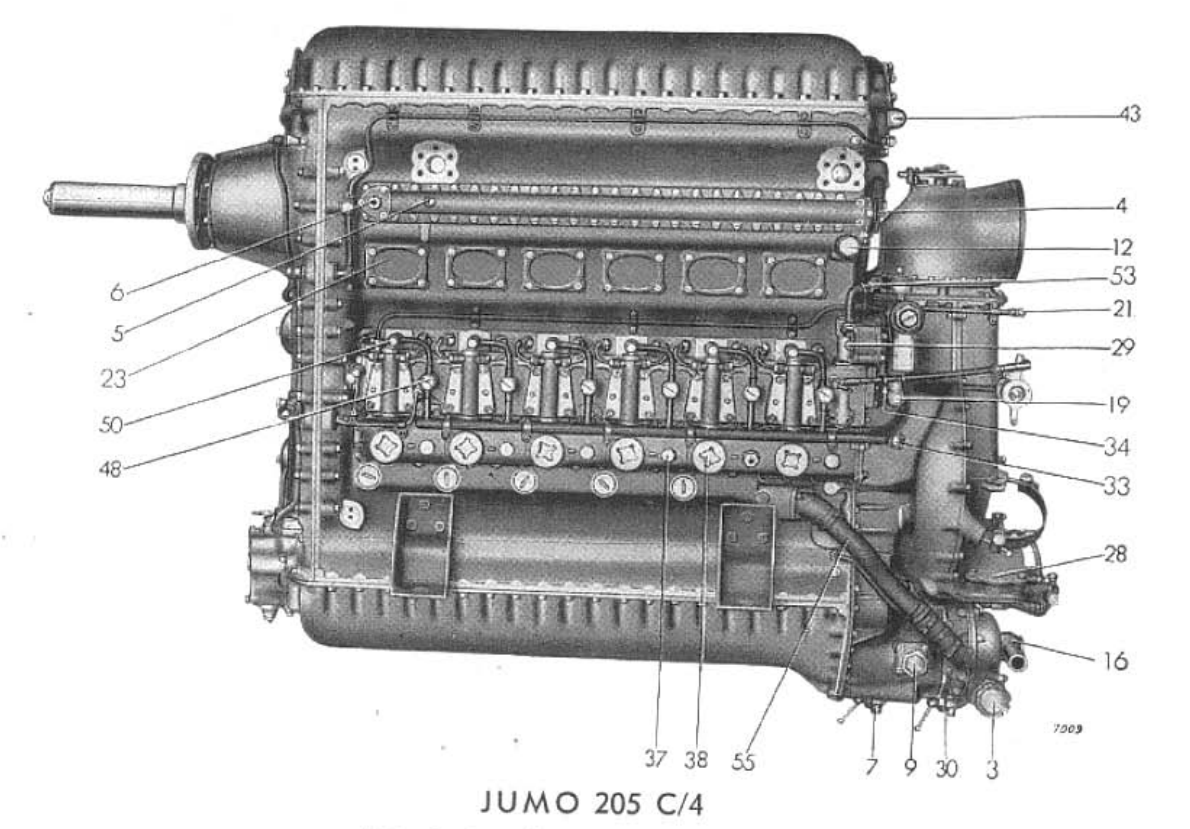

Commander Tanegashima’s greatest interest was mainly in the format of a propeller-driving gas turbine (turboprop) supplied by a free-piston compressor. At that time, the Navy had been developing the top-secret flying boat ‘H7Y1’ as a reconnaissance aircraft intended to make a round trip from the Marshall Islands to Hawaii. In order to achieve this range requirement of 5,000 nautical miles, four Jumo 205C opposed-piston engines imported from Germany were employed as a result of their low fuel consumption. However, when the prototype was completed in 1939 it suffered from many issues including lack of strength and rigidity, insufficient engine output, poor maneuverability, and more.

The prototype was canceled in July 1939, and all related materials including drawings and photos were destroyed, but the Jumo 205C engines were left over. The format of this engine was good for Tanegashima’s purposes, and he started a project with Mitsui Co. in 1940 to prototype a free-piston compressor by diverting the cylinders of the Jumo 205C.

However, the design of the compression piston diverted from the Jumo 205’s opposed pistons required a large amount of design innovation, and while the project was idling, Commander Osamu Nagano who worked in the Engine Department under Tanegashima designed a tiny model gas turbine with a free-piston. In 1941, it was manufactured by Mr. Masanori Miyata, head of the electronics factory, and after work applying corrections, it was able to reciprocate smoothly and operate continuously.

This micro gas turbine only had an output of 1/10th horsepower, but it was able to demonstrate itself by driving a small magneto to light an electric lamp, and inspired hope and courage in the young engineers working day and night. Although it was only a ‘toy’, it was technically the first gas turbine manufactured in Japan, and sadly disappeared in time without even a photograph.

The Tanegashima Group, 2nd Research Branch

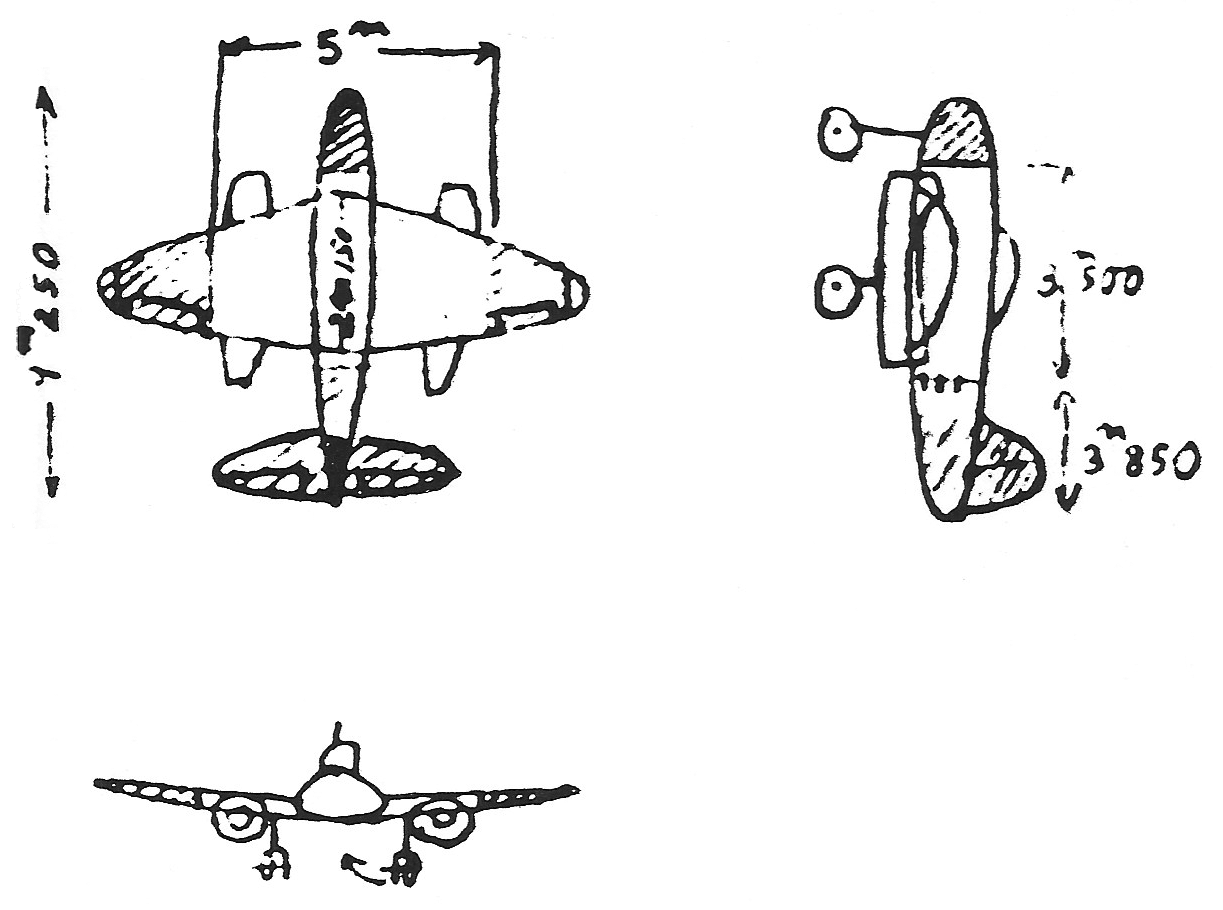

British jet plane.

Then came about the 8th of December 1941, when the Japanese Navy conducted an attack on the United States Navy at Pearl Harbor. Tanegashima recalled an overwhelming sense of dread that a giant was being awoken. Around this time, he had also learned from a Navy intelligence officer that England had tested a jet plane earlier in May. After a few days, Tanegashima decided that the jet engine must be developed at any cost to vastly increase the performance of aircraft, lest Japan fall far behind the western world in aviation technology which would undoubtedly spread from England to the USA. He immediately appealed to his superior, chief of the Engine Department Rear-admiral Kiyoshi Matsukasa, to be able to focus solely on this subject. The request was immediately accepted, and in January 1942 Tanegashima was appointed as the chief of the 2nd Research Branch focused on jet engine development, with several skilled engineering officers and roughly 200 workmen at his disposal. One of these engineers was Shigeo Katō, a 1st Technical Lieutenant who was said to have an even deeper understanding of the gas turbine than Tanegashima.

After the failure to manufacture a free-piston based on the Junkers engine, Tanegashima had realized that the current Japanese industry was unable to manufacture such a machine. During the middle of the year 1942, it was learned that the Italian Caproni Campini N.1 had flown without a propeller, garnering much public interest, and it was also disclosed by confidential means that the Germans had tested a jet plane long ago. Thus, the focus drifted away from the free-piston, and eventually it was shelved in favor of the conventional turbojet engine, which was speculated to be the power plant of what was the ‘He 178’.

During the early phase of official jet engine development under Tanegashima’s Group, several theoretical reports on different types of jet engines and gas turbines were published. The main types studied were the TR (turbine rocket, now turbojet), GTPR (gas turbine propeller rocket, now turboprop), similar compound variations, and the Campini type (motorjet). From these reports, it can be seen that Tanegashima was far in favor of the axial compressor, as opposed to the centrifugal-type common among the early jet engines of the world. However, the quickest way to procure an experimental jet engine was to convert from a turbocharger, which contain a centrifugal compressor.

In August 1942, one Hitachi turbocharger for a 2,000hp aero-engine was converted to a jet by installing a combustion chamber. During wind tunnel testing, though, it could not self-drive with combustion due to fundamental differences between a small turbocharger and a jet engine. This small unnamed machine, albeit a failure, was the first attempt to prototype a turbojet engine in Japan.

The First Japanese Turbojet Spins

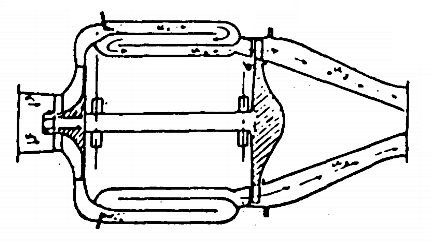

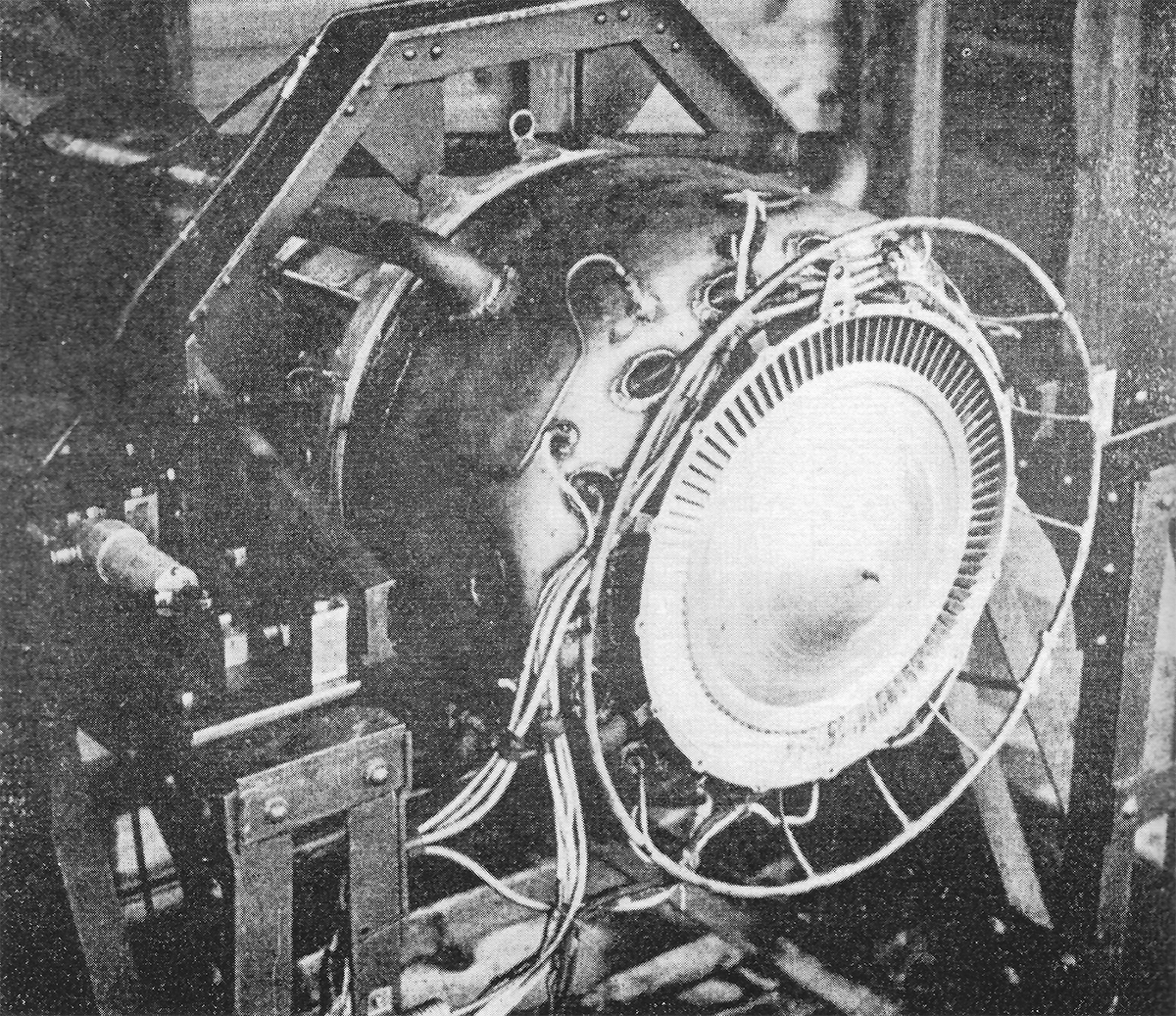

Japanese turbojet engine.

A much larger turbocharger designed by Shigeo Katō was delivered from Ebara during the next month. It was the YT15, a huge device with a turbine diameter of 600 mm and compressor diameter of 500 mm designed for engines of 2,500 hp at altitudes of 15,000 m. However, due to low turbine strength, the YT15 was not adopted as it was. Instead, Katō proposed its conversion into a turbojet due to its large size, and the conversion started at Ebara in February 1943. A complicated folded combustion chamber was installed due to the small distance between the compressor and turbine, and the exhaust pipe was remade as a jet nozzle. The initial engine was completed in June 1943 as Japan’s first functional turbojet, ‘TR’. The design targets were 16,000 RPM, 4.0 pressure ratio, and 300 kg thrust output.

| Thrust | 300 kgf (Plan) |

| Revolutions | 16,000 RPM |

| Pressure Ratio | 4.0 (Plan) |

| Format | 1C-AN-1AT |

Testing with TR started in July when the engine was placed at the mouth of a wind tunnel at 5 m/s wind speed. When it started to turn, vaporized fuel was injected into the combustion chamber and ignited with an electric spark. When the wind was stopped, all that was left was the hum of TR operating on its own power. The fuel quantity was increased, and the engine rapidly reached a speed of 14,000 – 17,000 RPM with a pressure ratio of 3.5, but there was no nozzle, so thrust was not produced. After about 5 minutes of full-power operation, it was stopped. Cracks were observed in the turbine blades.

Nonetheless, Tanegashima, Katō, and all were elated, as their theories had been proven. Now what was left was to produce a reliable jet engine, which proved to be the longest road of all.

One day, when running at full operation, there was a tremendous explosion and the TR was left in ruin. The centrifugal compressor, which was only made of cast aluminum due to lack of strong light alloy, burst into three pieces. One pierced the tin roof of the test bench, and two stuck into the surface plate on the floor. Fortunately, nobody was injured.

Whittle Unit 3

Soon, the second TR engine was delivered from Ebara. Changes to this unit included a forged compressor wheel and slightly reinforced turbine blades. During the first test of unit two, it was carefully brought up to maximum driving speed, then stopped after a few minutes and completely disassembled to inspect its condition. Once again, there were cracks in the base of the turbine blades. However, there was no time to perform repairs, so in order to record the thrust as quickly as possible, Tanegashima ordered Katō to mount the tailpipe and scraped off the cracked parts of the turbine with a file.

The engine was brought back up to full power operation, and as expected, the weakened turbine blades splintered off. Still not stopping the experiment, Tanegashima cut off the blades diagonal to those lost during operation and continued to drive it at full power several times. As the number of blades decreased, the backpressure increased and the RPM of the turbine decreased, but the corresponding thrust was still generated. Eventually, only a bladeless and tattered turbine wheel remained, but the generation of 250 kg of thrust had been confirmed.

After that, the third unit was built and testing continued for several months. However, constant issues including cracking of turbine blades, failure of compressor bearings, burn-through of the combustion chamber folds, and distortion of the nozzle plate into the turbine were inescapable, and the environment around Tanegashima began to sour as people became fearful of the dangerous engine. To counteract the complaints, sandbags were piled around the unit in a ‘bunker’, and viewing during operation was done through a mirror placed behind it.

Improvement of the ‘Turbine Rocket‘

Up until this time, the Navy had generally been indifferent to the jet engine experiments conducted by Tanegashima, and even planned to dissolve his research branch at one point in order to contribute to more practical areas.

However, in the early summer of 1944 a group of elite air officers stepped into a class where Tanegashima was teaching jet propulsion to officer candidates. Interest among the higher officers of the Navy had been piqued by reports concerning the application of jets in Germany. Immediately work on jet engines was given high priority, and the head of the Kūgishō, Vice-admiral Misao Wada ordered the work to be completed as soon as possible, instructing other departments to assist the development.

In July 1944 the experiments with the first 3 TR engines concluded, and the results plainly showed that there was still a long road to practicality. In an attempt to remedy the various issues, the design was improved and renamed ‘TR10’, and the Navy General Staff issued a rapid improvement plan. TR10 was ordered to be mass prototyped with iteratively refined designs in 70 units by 6 companies (Kūgishō, Mitsubishi, Nakajima, Hitachi Manufacturing, Ishikawajima Aircraft, Ishikawajima Shibaura Turbine) from the beginning of July to the end of August 1944 for rapid trial and error. The 6 companies formed 3 groups for production: Mitsubishi & Nagoya Kobe, Nakajima & Hitachi, and Ishikawajima Aircraft & IST. Each group was expected to complete 20 engines, with the Kūgishō completing another 10, for the 70 total.

| Dimensions | Length: 1,600 mm Diameter: 850 mm |

| Weight | 250 kg |

| Thrust | 300 kgf |

| Revolutions | 16,000 RPM |

| Pressure Ratio | 3.5 |

| Format | 1C-AN-1AT |

The Navy had suddenly promoted such an unlikely plan due to enthusiasm about combat reports of the German jet fighter ‘Me 262’. Unfortunately, there was a lack of confidence in the design of the obviously unfinished TR10 throughout the manufacturing companies, even if it was improved, and most companies were already overwhelmed with work on piston engines. As a result, the mass-prototype plan progressed painfully slowly. Only a few units seem to have been built.

Furthermore, at the end of that July, Commander Eiichi Iwaya returned from Germany with a cutaway drawing of the BMW 003A turbojet engine that was in practical use at the time, garnering a massive interest from the Army and Navy. The companies initially assigned to mass-prototype the TR10 were instead assigned three different large-scale turbojets for jet fighters, and the TR10 rapid improvement plan was all but canceled, once again solely in the hands of the Kūgishō. At this time, the jet development of the Army and Navy was merged into a joint effort, and the TR10 was renamed once again to the joint designation ‘Ne-10’ (‘Ne’ for ‘nenshō’, combustion).

When Tanegashima observed the BMW 003A drawing, he immediately recognized that it was of the same principle as the Ne-10, but employed a 7-stage axial compressor and lower turbine RPM, which greatly reduced the stress on the turbine blades. However, Tanegashima considered himself to be an ‘experimental researcher’ pioneering new technology by his own intuition, and recognized that if the Ne-10 was to be practicalized in a timely manner, a professional designer was necessary.

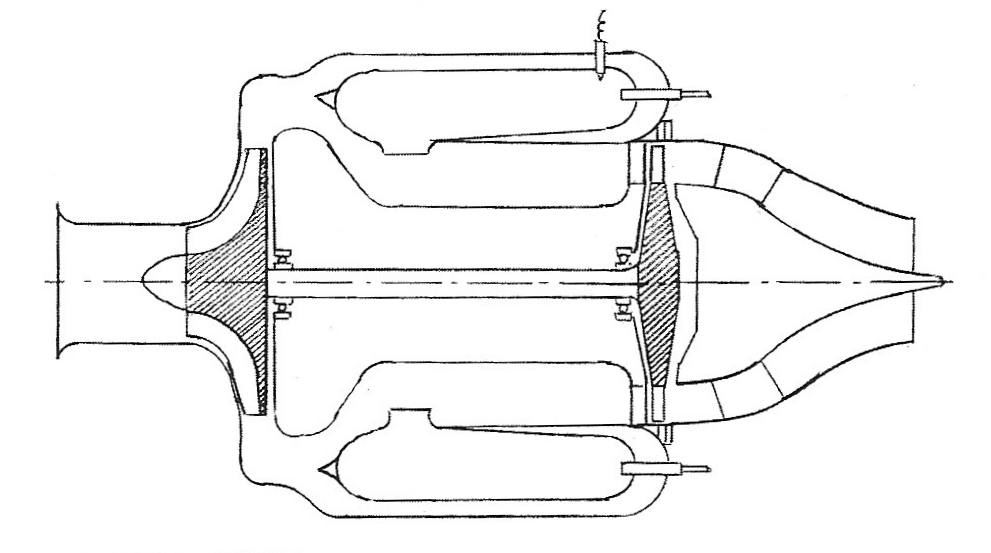

So, even before the first ‘Ne-10’ engine was completed in September and proved to be unsatisfactory, Osamu Nagano joined the Tanegashima group in August and started the design of a new engine in the series, Ne-10 Kai (Ne-10 Improved). Ne-10 Kai employed a 4-stage axial compressor ahead of the centrifugal compressor, which lowered the rotations of the turbine to 15,000, a much-needed stress reduction.

At the same time, a huge version of Ne-10 Kai called ‘Ne-30’ with a powerful projected output of 850 kgf was also planned. Furthermore, during October another version of the Ne-10 Kai with two fuel pumps for mounting to an aircraft (G4M) was designed, called the ‘Ne-12’.

The first unit of the Ne-10 Kai, Ne-12, and Ne-30 were all completed in November 1944. One more unit each of Ne-10 Kai and Ne-12 were completed before the end of that year. By this point, the material strength situation had improved somewhat. During running tests to gather data, these two engine models apparently managed 30 minutes of full-power operation before turbine cracking began, and the planned thrust output of about 320kgf was reached. However, the same issues such as damage to the compressor, unstable combustion, and turbine cracking continued, so this result was still far from satisfactory. The future of the Ne-10 series was in doubt.

On the other hand, the massively upscaled Ne-30 was deeply troubled for the same fundamental reasons as the rest of the series, only magnified by the increased size of the turbine and other components, and never could operate at full power before its abrupt cancellation.

The End of the Ne-10 Series

The final model of the Ne-10 series, the ‘Ne-12B’, was a finished design at the end of December 1944. This version most notably reduced the weight of Ne-12 from 388 kg to 315 kg and further reinforced the various components.

At the same time, Tanegashima expressed that the Ne-12 and its series were fundamentally flawed, and if the jet engine was to become practical, it was necessary to pursue a design based more closely on the format of the German BMW 003 type.

“I would like to express my gratitude for the efforts that brought Ne-12B to this point, but it seems that this engine is underdeveloped. At this time, it would be wise to tear down all of the past and restart with reference to the BMW 003A.”

Tokiyasu Tanegashima, Wagakuni ni okeru Jetto Enjin Kaihatsu no Keika

As it was, the strength of materials available at that time in Japan simply could not bear the heat and stress placed upon the turbine of a centrifugal turbojet, even with the additive compressor, and there were many other unsolved issues such as combustion problems which would be negated by adopting the German straight flow style. Furthermore, Tanegashima always believed that the pure axial compressor was the best method from the beginning, and the decision to use a centrifugal compressor was only due to the time and manufacturing constraints.

Between the arrival of BMW 003A’s drawing in Japan to this point, the Kūgishō had been conceptually drafting a new engine model based on the Ne-12. This engine called ‘Ne-15’ had the same performance requirement, but featured an 8-stage axial compressor derived from the BMW 003A format. By December, this plan had evolved into the ‘Ne-20’ with an improved projected output of 480kgf. Now all efforts were to be focused on the prototyping and testing of Ne-20, and the design improvement of the Ne-10 series was put on hold.

Even if the development of the ‘Ne-10’ series was discontinued, around this time the prototype of the jet-propelled special attack plane ‘Kikka’ was announced. Although heavily flawed, ‘Ne-12’ was the most advanced turbojet model available in actual testing, so there was no choice but to ignore the problems for the time being and select it as the powerplant. Furthermore, manufacturing and testing models of the Ne-12B as a sort of ‘prototype’ for the Ne-20 could provide valuable developmental data, as it was the most improved version of the Ne-10. For these reasons, the production of Ne-12B engines was ordered from the Yokosuka Yard, Hokushin Electric Works, Ishikawajima Shibaura Turbine, Masada, and Ebara. This order was very reminiscent of the ‘TR10’ mass-prototyping plan, and unsurprisingly, similarly failed to proceed.

| Dimensions | Length: 2,102mm (Ne-12) / 1,800 mm (Ne-12B) Diameter: 855 mm (Ne-12 & Ne-12B) |

| Weight | 388 kg (Ne-12) / 315 kg (Ne-12B) |

| Thrust | 315 kg (Ne-12) / 320 kg (Ne-12B) |

| Revolutions | 15,000 (Ne-12 & Ne-12B) |

| Pressure Ratio | 1.67 x 2.0 (Ne-12 & Ne-12B) |

| Fuel Efficiency | 1.65 kg/h/kgf (Ne-12B) |

| Format | 4A-1C-AN-1AT (Ne-12 & Ne-12B) |

From January to April 1945, just 12 units of the Ne-12B were constructed, 6 by the Kūgishō and 6 by the Yokosuka Navy Yard, with evidently none being built by private organizations. The first unit was completed in February. After some time, one unit was able to operate at full power for an hour, but the characteristic flaws such as combustion issues and turbine cracking continued. Even after almost two years of development labor, the final model of the ‘Ne-10’ series, with many incremental improvements, was little different from the first in practice.

The final nail in the coffin for the Ne-10 series came with the testing of the first unit of ‘Ne-20’ in late March 1945. Very quickly this format of an engine, running out of a cave behind the Kūgishō, proved to be more reliable, durable, and powerful than the entire centrifugal series before it. This is not to imply that the Ne-20 did not have its own set of issues, but these were far more manageable. The last tether of the Ne-12, its application to the special attacker ‘Kikka’, was severed on the 19th of April during a meeting at the newfound Jet Department of the Kūgishō, the results of which were phoned from the Navy Air HQ to Nakajima the same day.

“It was decided that Kikka will be equipped with Ne-20. Carry forward the prototype according to that point.”

Mr. Nozaki of Navy Air HQ to the 2nd Mfg. Plant

As a result, the production of the Ne-12B stopped in April. The development of the first Japanese turbojet series was over without practical use. Nonetheless, the Ne-10 series was an impressive technological endeavor from a nation that had only recently become aeronautically independent, with essentially no outside assistance and a lower level of materials science than the western world at the time. These engines provided invaluable data and experience that boosted the indigenous development, which continued at the Kūgishō throughout 1945 until the end of the war. The Ne-20 engine was advanced from the start of design to completing service trials in a staggeringly quick 6-month period – perhaps the fastest turbojet development process of the war globally – and famously succeeded in flight mounted below the wings of the ‘Kikka’ on the 7th of August.

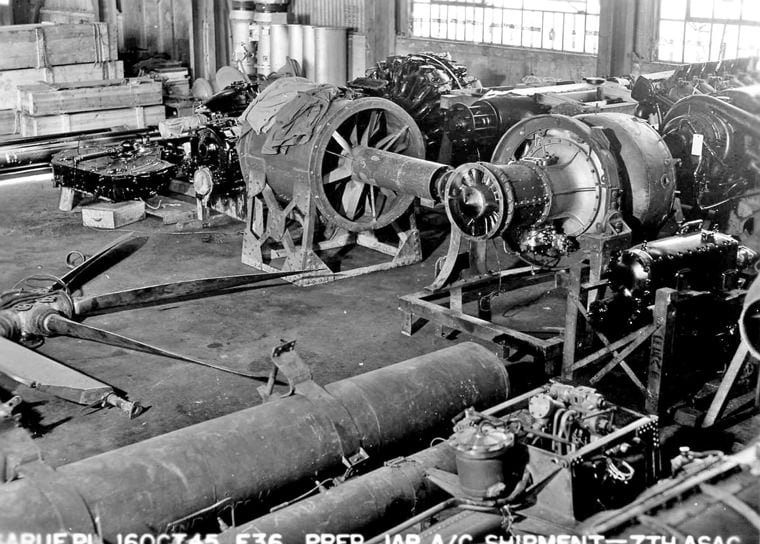

Fate of the Ne-10 Series

The whereabouts of these engines after the war are poorly recorded. In the photographs taken by the US Navy at the Kūgishō, among the various jet engines of the department, the following of the Ne-10 series are approximately identified by the author: 1x Ne-10, 1x Ne-30, 1x Ne-30 Mockup, 1x Ne-12(B).

Each of the Ne-10 and Ne-12 turbojets seem to have been scrapped at some point following the conclusion of the war. However, the 1st stage axial compressor fan of a Ne-12 remains preserved at the National Museum of Nature and Science in Tōkyō, Japan. This item bears the inscription “12B NO 4”, seemingly identifying it as part of the 4th Ne-12B made by the Yokosuka Yard.

Surprisingly, the largest of the Ne-10 series, ‘Ne-30’ still survives to this day. The sole prototype and its mockup have ended up in the storage of the Smithsonian Air and Space Museum, where they remain. At the time this article was written, Ne-30 is not displayed publically.

Unfortunately, apart from these three artifacts, no other remains are known to exist of Japan’s first turbojet series.

Sources

- Whittle, Frank. “The Early History of the Whittle Jet Propulsion Gas Turbine.” Proceedings of the Institution of Mechanical Engineers 152, no. 1 (1945): 419–35.

- Nagano, Osamu. “Kokusan jetto enjin monogatari.” Aircraft of the World no. 5 (1952): 75-81.

- Nagano, Osamu. “Senji-chū no jetto enjin kotohajime.” Tetsu-to-Hagane 64 no. 5 (1978): 659-663.

- Oshida, Yoshiteru. “Shūsen mae no Ebara gasutābin.” Journal of the Gas Turbine Society of Japan 25, no. 100 (1998): 64-66.

- Tanegashima, Tokiyasu. “Wagakuni ni okeru jetto enjin kaihatsu no keika (1).” Science of Machine 21, no. 11 (1969): 46-49.

- Tanegashima, Tokiyasu. “Wagakuni ni okeru jetto enjin kaihatsu no keika (2).” Science of Machine 21, no. 12 (1969): 46-48.

- Tanegashima, Tokiyasu. “Technical History of the Development of the Jet Engine in Japan.” Memoires of the Defense Academy, Japan X, no. 1 (1970): 1–32.

- Yoshida, Hideo. “Japanese Pioneers in Research and Development of Gas Turbine (1).” Journal of the Gas Turbine Society of Japan 46, no. 1 (2018): 1-34.

- Yoshida, Hideo. “Japanese Pioneers in Research and Development of Gas Turbine (2).” Journal of the Gas Turbine Society of Japan 46, no. 3 (2018): 55-71.

- Maema, Takanori. Jetto Enjin Ni Toritsukareta Otoko. Tokyo: Kodansha, 2003.

- Ishizawa, Kazuhiko. Kikka: Nihonhatsu No Jetto Enjin Ne nijū No Gijutsu kenshō Kaigun Tokushu kōgekiki. Tōkyō: Miki Shobō, 2006.

- Taisen Makki kōkū Kessen Heiki: Kikka Karyū Shūsui Ki 74. Tōkyō: Gakushū Kenkyūsha, 2006.

- Torikai, Tsuruo. Shirarezaru Gun yōki Kaihatsu (2nd). Tōkyō: Kantōsha, 1999.

- Rep. Reaction propulsion by Axial Flow Compressor, 1942.

- Rep. Free Piston Two-Stage-Combustion Internal Combustion Turbine and Turbine Rocket, 1942.

- Rep. Binding Related to Science and Technology, 1944.

- Rep. Development of Gas Turbine Propulsion in Japan, 1945.

- Rep. Miscellaneous Reports of Various Japanese Naval Research Activities, 1946.

Leave a Reply