Japanese Army Tank Optics

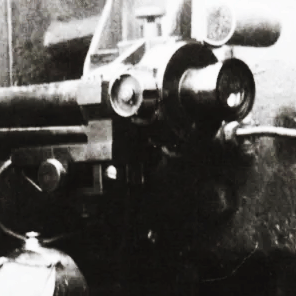

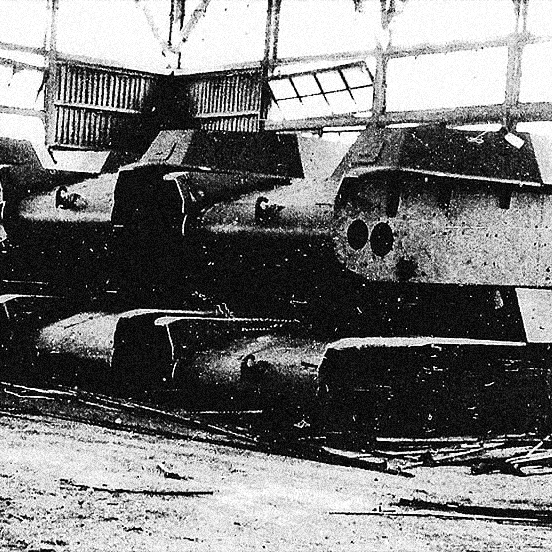

This article documents the basic specifications and development history of optical equipment used by the Japanese Army in its tanks and self-propelled guns during World War II. It covers the primary cannon sights, periscopes, rangefinders, and machine gun optics employed from the early Type 89 Medium Tank to late-war prototypes like the Experimental Type 5…