AIR TECHNICAL INTELLIGENCE GROUP

ADVANCED ECHELON FEAF

APO 925

FF12-5(25)

A8-2/F21

Serial No. 104

A.T.I.G. REPORT NO. 47

6 NOVEMBER 1945

Subject: GTPR, Turbo Supercharger, and Jet Engine Design and Development.

Reference: Air Staff Intelligence Requirements in the Far East, Section III A 1(a).

Persons Interviewed: Captain T. TANEGASHIMA, I.J.N.

Interviewing Officers: Captain S. B. SPANGLER, U.S.N. Commander J. H. MORSE, Jr., U.S.N.

Brief of Material Discussed:

Captain TANEGASHIMA graduated from the Naval Engineering College in 1922. From that time until 1930 he served in Marine Engineering assignments at Yokosuka and Kure during which period he did some work in steam turbine design. In 1933 he completed a three year course in the Aeronautical Department of the Tokyo Imperial University. Following this he served until 1945 at the First Naval Air Technical Arsenal at Yokosuka. Until 1941 he was Head of the First Plant which conducted type tests and was responsible for the development and proof of remedies for service difficulties. After 1941, probably because of his interest in gas turbine and rocket work, he was made head of research for Turbo Superchargers and Gas Turbines.

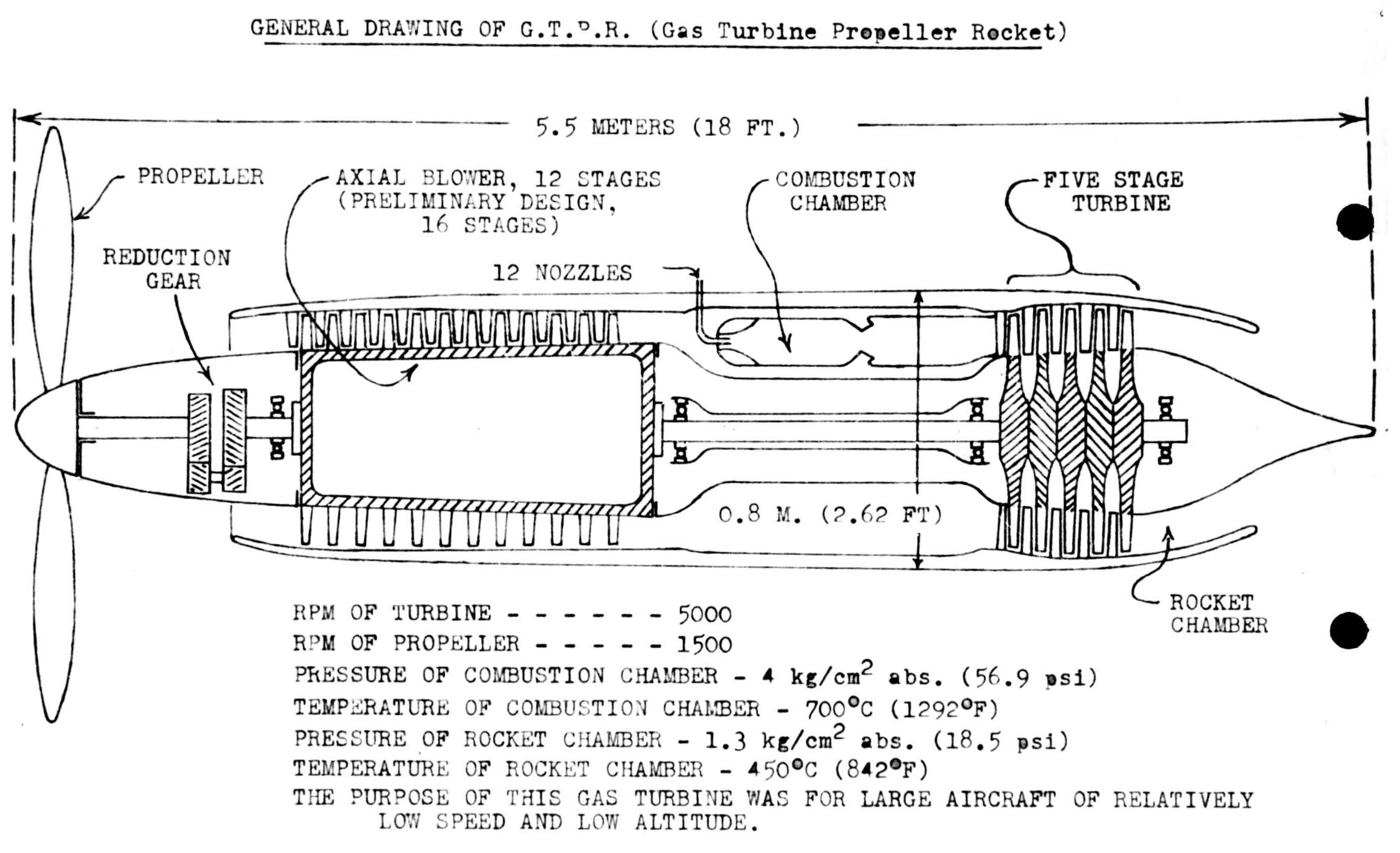

The GTPR (Gas Turbine Propeller Rocket) is a gas turbine propeller drive design developed in Japan since 1939, primarily by Captain TANEGASHIMA. Captain TANEGASHIMA first became interested in the design of the GTPR about six years ago after reading foreign literature about gas turbines and turbo superchargers. He claims that the initial idea for the GTPR design was entirely his own. For the first two years only design studies and fundamental tests were conducted. These fundamental tests consisted of work on compressor, turbine, and combustion chamber designs including the construction of full and part scale models. Since the Japanese were unable to construct full size components, a 1/4 scale model of the 16 stage axial compressor was constructed as well as a few full scale single compressor stages. A compressor efficiency of .75 was measured in the 1/4 scale model by the recording of temperatures. No attempt was made to measure power input or output. Professors from the University of Tokyo were consulted in determining blade design and angle. The theory for blade design assumed a constant velocity over the length of the blades and neglected the radial velocity. This resulted in twisted blades. A Clark Y section was used but when later experiments indicated the desirability of blades of increased camber a modified Clark Y was adopted. Ram velocity was measured as 120 meter/sec. (268 mils/hr). A compressor efficiency of .80 was assumed, although actual values were probably between .7 and .75. The anticipated pressure rise of 4.0 based on total pressure was almost attained in the 16 stage model. No lattice tests were conducted. A turbine efficiency of .7 was assumed but he thought an efficiency of 0.8 was attainable based on the results with the Ne 20 engine. A nozzle coefficient of .87 to .90 was assumed.

A number of experiments were conducted on obtaining proper atomization for good combustion. The device eventually adopted consisted of a gear pump with regulating by-pass discharging to a spray valve. This valve contained a helical passage which imparted a rotary motion to the fuel before its ejection in a cone shaped spray through a discharge orifice. Fuel flow was controlled by changing the fuel pressure through the by-pass adjustment. This fuel supply system was considered adequate for pressures of 3 to 30kg/sqCm (42.7 to 427 lbs/sq.in.). A ball check valve was incorporated to shut off fuel flow at pressures below the lower value. It should be realized that this fuel system was primarily a laboratory device for preliminary determination of principles of operation. A device of this nature if actually employed in operation would have undoubtedly failed because its fixed orifice nature would have been satisfactory for only a fixed pressure. Some form of variable orifice would have been necessary in practice.

The annular combustion chamber was a modification of the German BMW 003 design and contained 12 fuel nozzles of a type to be a result of experiments described above. Preliminary construction was of 18-8 stainless steel, but later construction was of mild steel coated with aluminum by a dipping process. No ceramic coatings were tried.

In July of 1944 a picture of a longitudinal cross sectional drawing of the BMW 003 was received from Germany. After much consultation it was decided that the war situation existing at that time would not permit expenditure of effort in long range projects such as the GTPR. Just as was the case in Germany the turbo jet was considered to be a more suitable power plant for high speed interceptor aircraft for defence of the home land and there fore all effort was directed toward making a direct copy of the 003. The Japanese had made no real studies of the possibilities of gas turbine propeller combinations since the GTPR was far from demonstrating any such performance and the propeller industry was in no position to estimate the future of suitable propellers for high speed aircraft. Consequently the Ishikawajima-Shibaura Turbine Company which had been assigned the task of constructing the first GTPR unit was directed to suspend work on this project and concentrate on design and construction of the Ne 130, its version of the BMW 003. However, through the personal effort and influence of Captain Tanegashima, the Ishikawajima company actually constructed the parts for one GTPR and had them ready for assembly when one of the August 1945 air raids completely destroyed the shop containing the parts. Consequently, the unit was never assembled and no data are available on its performance. The drawings at Ishikawajima were destroyed at the same time and the drawings which had been retained in the Naval Air Headquarters were destroyed immediately after the end of the war.

The GTPR design is of interest primarily as an example of relatively independent Japanese thought along the lines of jet and gas turbine design. However, the design was extremely primitive in many respects and can hardly be considered as anything more than a hurred reduction to a paper design of the results of elemintary thought and experimentation in this field. A number of the more important problems had not even been considered or had been only cursorily treated. It is probably that the final Japanese design is quite comparable to the Northrop Turbodyne in 1940. Since the Turbodyne was unsuccessful four years later it can be seen that the GTPR was far from a useable engine. Infact, it is probable that it would never have run itself to say nothing of delivering useful shaft horsepower.

Typical of the state of Capt. Tanegashima’s thought was the conviction that gas turbines were useful only in low altitude large aircraft because of what he considered to be unsolveable compressor and turbine design problems.

| INFORMATION ON NAVY GTPR. | |||

| Estimated | Actual | ||

| Efficiencies: | Turbine | .80 | .70 |

| Compressor | .80 | .70 | |

| Number of Stages: | Turbine | 5 | |

| Compressor | 12 | ||

| Pressure Ratio: | 4:1 (based on total head) | ||

| Weight: | 2500 kg total (5500 lbs) | ||

| Length: | 5.5 meters (18.0 feet) | ||

| Diameter: | .8 meters (31.5 inches) | ||

| Estimated Power: | 3500 propeller HP | ||

| (Sea level) | 1500 jet thrust HP at 600 km/h (373 mi/hr | ||

| Operating Temperatures | 700 degrees C. Combustion chamber, | ||

| 400 degrees C rocket chamber | |||

| Rated RPM: | Turbine 5000 RPM | ||

| Propeller 1500 RPM | |||

A sketch of GTPR is contained in Appendix ( A).

JET PROGRAM

Japanese interest in jet propulsion had been aroused about 1942 when word was received from Germany that such engines were in the practical stage. Initial efforts in jet design in Japan were directed toward a single centrifugal stage compressor and single stage turbine jet. A number of modifications of this initial design were tried until eventually it had grown into a four stage axial compressor followed by a single centrifugal stage and a single stage turbine. No designs then available appeared practicable. In July 1944 when the cross sectional drawing of the BMW 003 was received from Germany, a general conference of all interested parties was called and the decision made to concentrate immediately on the German type to the exclusion of all Japanese designed jets. To accomplish this, three companies were assigned projects to developed individual versions of the German engine. These companies were ISHIKAWAJIMA-SHIBAURA TURBINE COMPANY, NAKAJIMA ENGINE COMPANY in conjunction with HIDACHI TURBINE COMPANY, and the MITSUBISHI ENGINE COMPANY. Designations assigned these engines were respectively the Ne 130, Ne 230, and Ne 330. In addition the Navy undertook its own development at the First Naval Air Technical Arsenal at Yokosuka and designated its engine as the Ne 20. Of all these engines only the Ne 20 was successful. Bench tests of this engine were run from April to July 1945 and on August 6th the first successful flight of KIKKA was made using two of these engines. This first flight lasted for 21 minutes. At the end of the war between 10 and 20 KIKKA airplanes had been completed and sufficient Ne 20 engines built at Yokosuka were ready for them. Mass production was scheduled for these airplanes and engines. This statement is at variance with the statements of other personnel. To date no KIKKA airplanes have been found and only two Ne 20 engines have been located. The statement is being investigated.

Captain Tanegashima believed that the Ne 20 could be considered a successful engine at the end of the war. This statement is at variance with the official Navy estimate of 18 months development required before the engine could be considered practicable. It should be noted that Captain Tanegashima is probably an individualist whose opinions on the subject in which he is most interested would often differ from the official views of the Navy.

Much investigation and development still remained to be done at the end of the war. Preliminary troubles with blade cracking had been eliminated. However, the control problem had received little attention and little was known about tail cone position. Starting problems were not difficult. An electric starter capable of turning the engine at 6000 RPM was used, although starting was usually obtained at rotor speeds of 1500 RPM. This speed was reached in 10 to 15 seconds starter operation. Starting was accomplished on gasoline fuel. During acceleration the fuel supply was switched to pine root distilate fuel containing about 20 to 30% gasoline. Since the engine was not designed for starting in the air there was no problem involved in battery capacity. When making this statement, the prospective use of this engine in OKA 33 was probably overlooked. This version of OKA was to be carried by RENZAN (RITA). in such an installation it would obviously be necessary to start the Ne 20 at the release altitude. Judging from American experience the starting problem under such circumstances would have been more difficult than anticipated by the Japanese.

TURBO SUPERCHARGER DEVELOPMENT

The first attempts toward turbo supercharger design were initiated with the purchase of a Swiss Brown-Bovari unit in 1939. This unit was bench tested until 1941 and the results made available to several companies. In 1940 – 1941 three separate designs were started by Mitsubishi, Hidachi, and Ishikawajima and one unit built to each design. All three units were tested by the Navy and returned for correction of defects. These defects consisted of faulty bearings, oil leakage, and defective turbine blades. The Mitsubishi type of inserted blades came loose while the Hidachi welded construction showed faulty welding technique which caused broken blades. The Ishikawajima machined turbine was discarded as too difficult to produce. About 1942 a captured GE turbo supercharger was closely studied and furnished much useful information. As a result of experience with early designs and study of the GE unit, both Mitsubishi and Hidachi produced satisfactory turbo designs containing internal gear type oil pumps and internal bearings. The Hidachi unit was installed on SAIUN (MYRT) and BETTY for flight tests which were almost completed at the end of the war. The Mitsubishi installation on RAIDEN (JACK) was also in flight test status at the end of the war.

In general Captain Tanegashima considered that the actual construction of satisfactory turbo superchargers had been accomplished by the Japanese, but that all attempts at installation in airplanes had been poorly carried out. He attributed this poor performance in installations to the lack of experience and to the fact that there was no company in Japan which was good at installation work. Part of the blame for this situation could be attributed to the general lack of interest in supercharging until the advent of the B-29.

In addition to lack of interest Captain Tanegashima attributed the lag in turbo development to the following factors: (1) little technical knowledge on the part of pilots, including test pilots. (2) poor performance of all available propellers at altitude. (3) failure of engine manufacturers to incorporate proper ratio reduction gears. (4) Poor installations as discussed above.

Captain Tanegashima stated that pilots were afraid of turbo superchargers and did not like to fly them because of a false belief that they presented a fire hazard. He also thought that the unaccustomed appearance of high boost pressures at altitude incited a ear that the engine would fail under such power outputs at altitude. He considered that propeller design was a very definite limitation on increased supercharging until propellers of a better design were available. he stated that the Sumitomo Propeller Company was the only activity in Japan which might be expected to improve the propeller design, and that even they did not seem capable of producing satisfactory designs for this purpose.

Prepared by: J. H. MORSE, Jr.,

Commander, U.S.N.

Approved: F. O. CARROLL,

Brig.Gen., U.S.A.

Leave a Reply